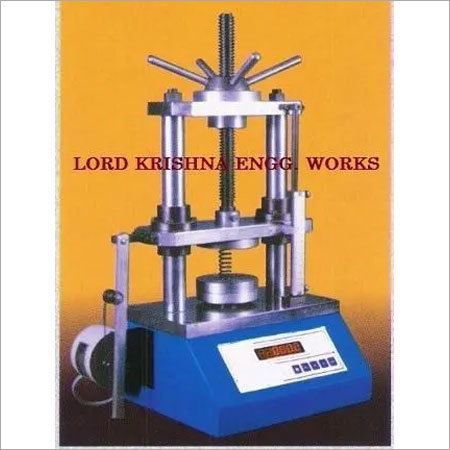

Flexure Testing Machine

MOQ : as per requirement Piece

Flexure Testing Machine Specification

- Operating Voltage

- 220V

- Max Height

- 1200 mm

- Frequency

- 50 Hz

- Number of Specimens

- 1 per cycle

- Equipment Type

- Flexure Testing Machine

- Interface Type

- RS-232 / USB

- Humidity

- Up to 85% RH

- Temperature

- 5C to 40C

- Measuring Range

- 0-100 kN

- Power Supply

- 220V AC, 50Hz

- Response Time

- < 1 second

- Port Size

- Standard Specimen Fixture

- Application

- Concrete Beam Flexural Strength Testing

- Accuracy

- 1% of indicated value

- Specimen Size

- 100 mm x 100 mm x 400 mm

- Test Range

- 0-100 kN

- Resolution

- 0.01 kN

- Display Type

- Digital LCD

- Automation Grade

- Semi-Automatic

- Mounting Type

- Floor Standing

- Features

- Microprocessor controller, Overload Protection, Data Storage

- Usage

- Material Strength Testing

- Capacity

- 100 kN

- Machine Weight

- Approx. 120 kg

- Test Speed

- 50 mm/min

- Test Width

- 150 mm

- Test Stroke

- 0-100 mm

- Control Mode

- Digital Automatic

- Load Sensing System

- High precision strain gauge based

- Safety Features

- Mechanical and electrical overload protection

- Ambient Conditions

- Non-corrosive, dust free environment

- Data Output

- USB export, real-time graph

- Color

- Industrial blue & white

- Operating Noise Level

- < 60 dB

- Frame Construction

- Heavy duty welded steel

- Crosshead Clearance

- Approx. 800 mm

- Software Support

- PC data acquisition software

- Digital Indicator

- Backlight 5-inch display

- Protection System

- Emergency stop push button

- Calibration Method

- Manual & Automatic

Flexure Testing Machine Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 1 Week

- Packaging Details

- normal

- Main Export Market(s)

- Australia, North America, Eastern Europe, Western Europe, Africa, Central America, Middle East, South America, Asia

- Main Domestic Market

- All India

About Flexure Testing Machine

We offer flexibility testing machine for checking the mechanical solidness of adaptable lines and links by twisting them forward and backward, this test applies just to adaptable links with centers of ostensible cross-sectional region lower than 42. Our testing machine comprises of a transporter, with recycling metal ball brambles running underneath the table-board on two round and hollow guideways, with mounted voyaging blast, equipped engine with tie and associating bar to drive the bearer with a speed 0.33 m/s± 5%, set per test of screws and nuts for attaching the pulleys, set per test of controlling cinches and stops to confine the movement of the example.Advanced Load Sensing for Accurate Results

Equipped with a strain gauge-based load sensing system, this machine delivers highly reliable and repeatable testing results for concrete beam flexural strength. The digital indicator provides instant feedback, while real-time graphing and PC software support streamline analysis and reporting.

Robust Construction and Built-In Safety

Constructed with heavy-duty welded steel, this equipment ensures durability and longevity under industrial testing conditions. Complete with emergency stop and mechanical/electrical overload protection, it prioritizes operator safety alongside rigorous performance.

Seamless Data Management and User Experience

The digital LCD interface, USB export capabilities, and advanced microprocessor control simplify testing workflows. Data storage and PC acquisition software enable comprehensive record-keeping and analysis, making it ideal for compliance and quality assurance applications.

FAQs of Flexure Testing Machine:

Q: How does the Flexure Testing Machine ensure testing accuracy?

A: The machine utilizes a high-precision strain gauge-based load sensing system, offering accuracy within 1% of the indicated value and a resolution of 0.01 kN. Calibration can be performed both manually and automatically for consistent, dependable results.Q: What is the process for conducting a flexure test on this machine?

A: To conduct a test, mount a specimen of 100 x 100 x 400 mm on the fixture, set the required parameters using the digital interface, and initiate the automated test sequence. The machine applies force at 50 mm/min until specimen failure, recording force and displacement in real time.Q: When should calibration be performed on the machine?

A: Calibration should be conducted regularly as advised by your quality control standards or after any significant maintenance. Both manual and automatic calibration modes are possible, ensuring the testing remains within specified accuracy limits.Q: Where is data from the tests stored and how can it be exported?

A: Test data is stored within the machines internal memory and can be exported via USB or RS-232 interface. Additionally, real-time graphs and results can be transferred to PC data acquisition software for comprehensive analysis and report generation.Q: What safety features are integrated into the machine?

A: The equipment is fitted with an emergency stop push button, mechanical and electrical overload protection, and operates with low noise (< 60 dB), ensuring a secure and comfortable environment for users.Q: How does the machine benefit concrete testing labs and manufacturers?

A: Its high accuracy, digital control, and robust construction ensure repeatable, standardized results, streamlining material strength evaluation and meeting regulatory compliance. The user-friendly interface and software integration further enhance productivity and documentation efficiency.Q: What are the ideal environmental conditions for operating this machine?

A: Optimal performance is achieved in non-corrosive, dust-free environments with ambient temperatures between 5C to 40C and humidity up to 85% RH, ensuring longevity and measurement stability.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Laboratory Testing Machine Category

Tyre Testing Machine

Price Range 150000.00 - 600000.00 INR / Piece

Minimum Order Quantity : as per requirement Piece

Usage : Lab & Industrial tyre testing

Test Speed : 1060 rpm

Spring Load Testing Machine

Price 98500 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Product Type : Manual,Motorized

Test Speed : Variable speed

Compression Testing Machine

Price 35000 INR / Set

Minimum Order Quantity : 1 Set

Usage : Industrial

Test Speed : Variable

Digital Spring Testing Machine

Price 1 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Product Type : Spring Load Testing

Test Speed : Constant

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese